The Importance of CNC Machining Parts in Manufacturing Industries

Introduction

In today's manufacturing industry, precision and efficiency are paramount. One of the most important aspects of achieving these goals is the use of CNC (Computer Numerical Control) machining parts. CNC machining has revolutionized the manufacturing industry, enabling the production of high-quality and complex components with unparalleled accuracy and speed. In this article, we will explore the importance of CNC machining parts and how they are helping to shape the modern industry.

What is CNC Machining?

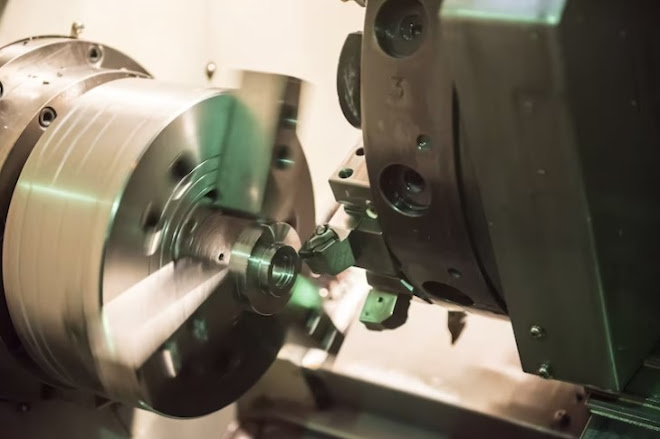

CNC machining is a process that involves the use of computer-controlled machines to manufacture parts and components. The process uses a variety of cutting tools to remove material from a raw material, such as metal or plastic, to create a specific shape. CNC machines are capable of producing a wide range of shapes and sizes with incredible accuracy, making them ideal for high-precision applications.

The Benefits of CNC Machining Parts

CNC machining parts offer a number of advantages over traditional manufacturing methods. One of the biggest benefits is their ability to produce complex components with a high degree of accuracy. This is achieved by using computer-controlled machines that can continuously monitor and adjust the cutting process, ensuring that the final product meets the required specifications.

Another advantage of CNC machining parts is their speed and efficiency. CNC machines are capable of producing components much faster than traditional methods, reducing production time and increasing productivity. Additionally, the use of CNC machines reduces the risk of human error, resulting in fewer defects and a more consistent product quality.

CNC Machining Services

JC Machining is a leading provider of CNC machining services, offering a range of services including CNC turning, CNC grinding, and CNC milling. With over 30 years of experience in the industry, they have established themselves as a trusted and reliable partner for businesses across a range of industries.

One of the key advantages of working with a company like JC Machining is their commitment to R&D innovation. By constantly upgrading their technologies and quality control capabilities, they are able to deliver the highest quality products to their customers. Additionally, their dedication to customer satisfaction has helped them to build a reputation as one of the leading providers of precision mold parts in Taiwan.

Applications of CNC Machining Parts

CNC machining parts have a wide range of applications across a variety of industries. In the medical industry, CNC machining is used to produce high-precision components for surgical instruments and implants. In the aerospace industry, CNC machining is used to manufacture components for aircraft engines and other critical systems. CNC machining is also used in the automotive, electronics, and telecommunications industries to produce a range of components and parts.

Conclusion

In conclusion, CNC machining parts are an essential component of modern manufacturing. They offer unparalleled accuracy, speed, and efficiency, making them ideal for high-precision applications. Whether you are in the medical, aerospace, automotive, or any other industry, CNC machining can help you to achieve your manufacturing goals. With the help of companies like JC Machining, businesses can take advantage of this technology to produce high-quality components and stay ahead of the competition.

Comments

Post a Comment